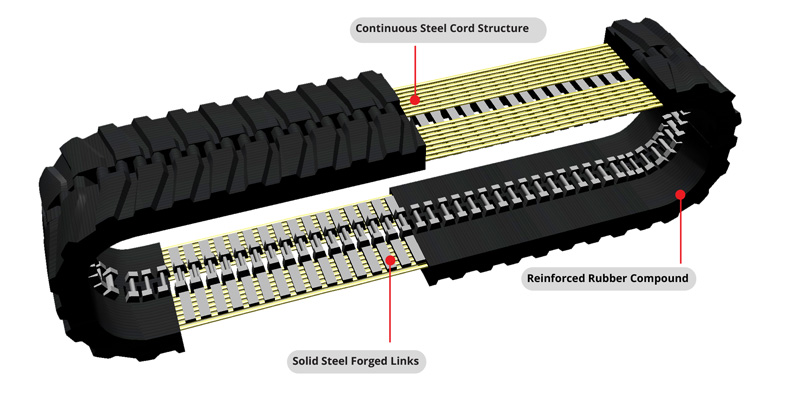

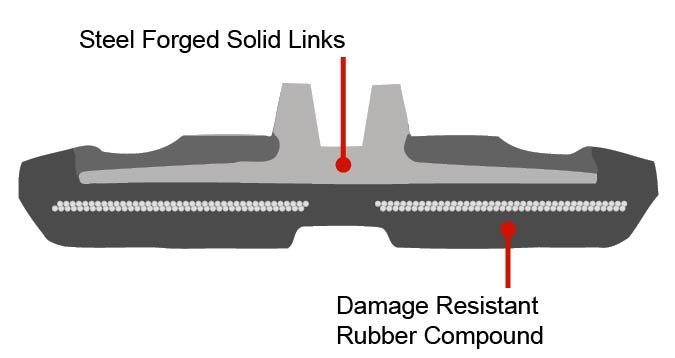

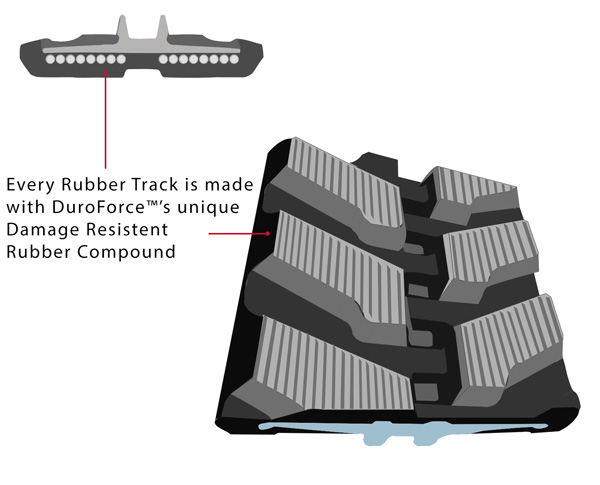

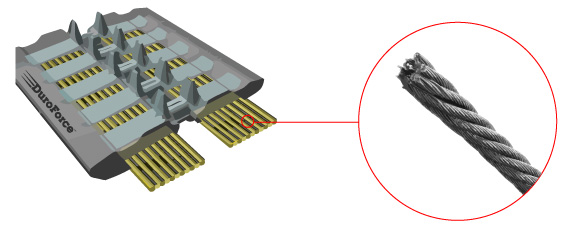

DuroForce™ manufactures aftermarket rubber tracks for mini excavators. Our aftermarket tracks meet or exceeds all standards set by the OEM equipment manufactures.

We have been continuously refining our manufacturing process to produce the best aftermarket rubber tracks for excavators and will continue to do so to ensure our customers receive a superior product at a better price then other products.