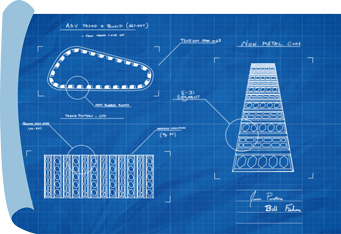

DuroForce™ manufactures ASV Style rubber tracks for track loaders. Our aftermarket rubber tracks follow the same specifications and quality testing of equivalent the OEM rubber tracks. We have been continuously refining our manufacturing process for these Kevlar non-metal core rubber tracks and will continue to do so to ensure our customers receive a superior product at a discount price.

ASV Style Rubber Tracks

Design & Construction

Tread Designs – Duroforce’s tread design for this type of track matches that of the OEM tread. Over years of testing, this tread pattern has proven to increase durability when compared to other tread designs by reducing the force on the weak and higher stress points around the tread.

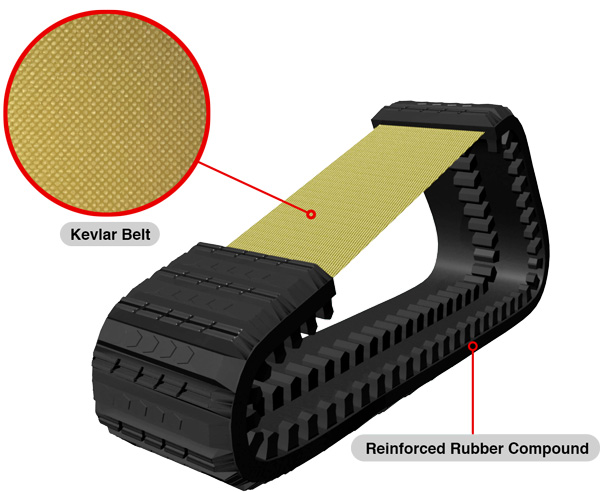

Kevlar Belt Core – DuroForce began to try and make a ASV Style track in 2006. After years of testing we found the best way to make this track was to form the track around a central Kevlar belt core. This design provided unparalleled strength in this type of track.

Rubber Compound – DuroForce has developed a rubber compound blending process that is unique in the industry. The Rubber we use contains virgin rubber, carbon black, and many other compounds, and materials to aid in the strength, and durability of our ASV Style rubber tracks.

This formula also significantly minimized the chunking and cut damage caused by sharp objects. This increases the lifespan of the track and reduces the chance premature breakage.

Tread Pattern Options

DuroForce offers two different tread patterns to fit most machines.

- OEM Style Tread Pattern – This tread pattern was based off the original OEM tread pattern that ASV developed.

- Smooth Turf Tread Pattern – This tread pattern is designed for use in turf applications such as golf courses and parks.

ASV OEM Style Tread Pattern

ASV Style Smooth Turf Tread Pattern

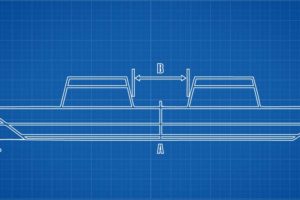

Track Identification

- Identify the number of rows of lugs that engage the sprocket. 1, 2 or 3.

- Identify the quantity of lugs going around the track in 1 of the rows.

- Identify the width of your track.

Using the chart below, you should now be able to identify your track by the 2nd, 3rd and 5th columns.

Track Specifications

| Track Size | Lugs Per Row | Rows of Lugs | Pitch | Track Width (A) | Lug Height (mm) (B) | Track Carcus (mm) (C) | Tread Thickness (mm) (D) | Tread Pattern |

|---|

| 11x4x37 | 1 | 37 | 4" | 11" | 48 | 18 | 28 | D6 |

| 15x4x42 | 1 | 42 | 4" | 15" | 45 | 21 | 25 | D6 |

| 15x4x51 | 1 | 51 | 4" | 15" | 45 | 21 | 25 | D6 |

| 18x4x51 | 2 | 51 | 4" | 18" | 46 | 24 | 23.5 | D6 |

| 18x4x56 | 2 | 56 | 4" | 18" | 46 | 24 | 23.5 | D6 |

| 18x4Cx51 | 3 | 51 | 4" | 18" | 46 | 24 | 23.5 | D6 |

| 20x4Cx51 | 3 | 51 | 4" | 20" | 46 | 24 | 23.5 | D6 |

Machine Application

ASV

- 2800, 2810, 4810, HD4500, HD4520, MD70, DX4530

- RC30, RC50, RC60, RCV, RC85, RC100

- SR70, SR80

- PT30, PT50, PT60, PT70, PT80, PT100

- RT25, RT30, RT40, RT50, RT60, VT70, RT75, RT110, RT120, RT135

Caterpillar

- 247, 247b

- 257, 257b, 257b2, 257b3, 257d

- 267, 267b

- 277, 277b, 277c, 277c2, 277d

- 287, 287b, 287c, 287c2, 287d

- 297c, 297d, 297d-xhp

Terex

- PT30, PT50, PT60, PT70, PT75, PT80, PT100, PT100g, PT110

- R070t, R160t, R190t, V235t, R265t, R350t