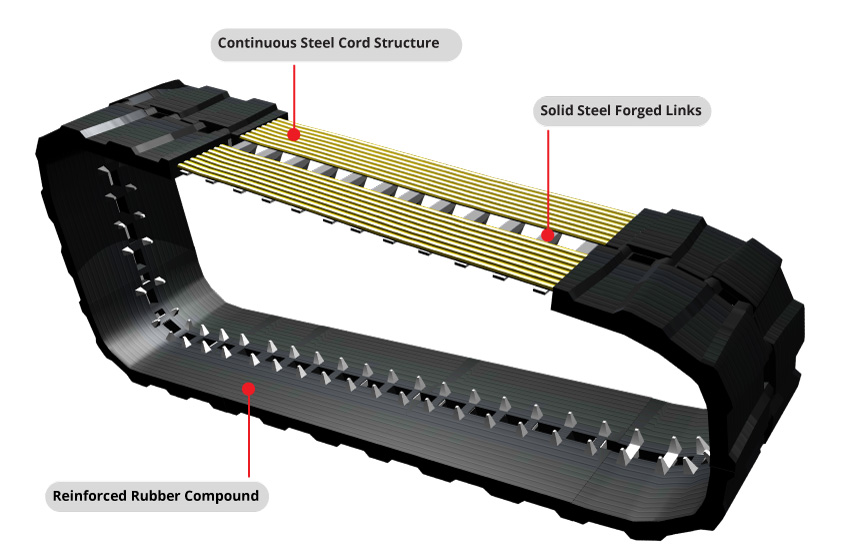

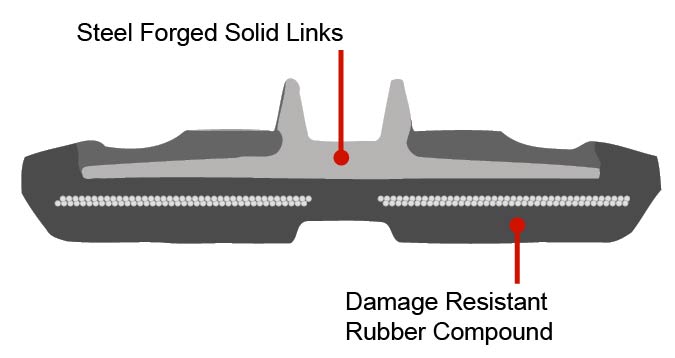

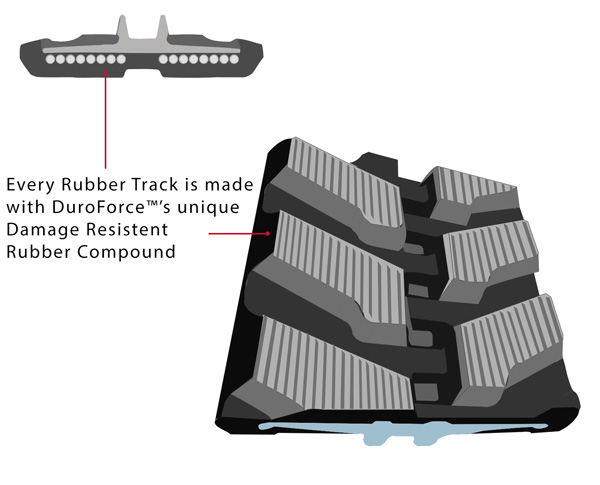

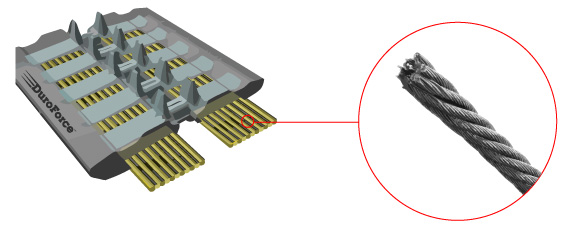

DuroForce™ manufactures aftermarket rubber tracks for compact track loaders. Our aftermarket tracks meet or exceeds all standards set by the equipment manufactures.

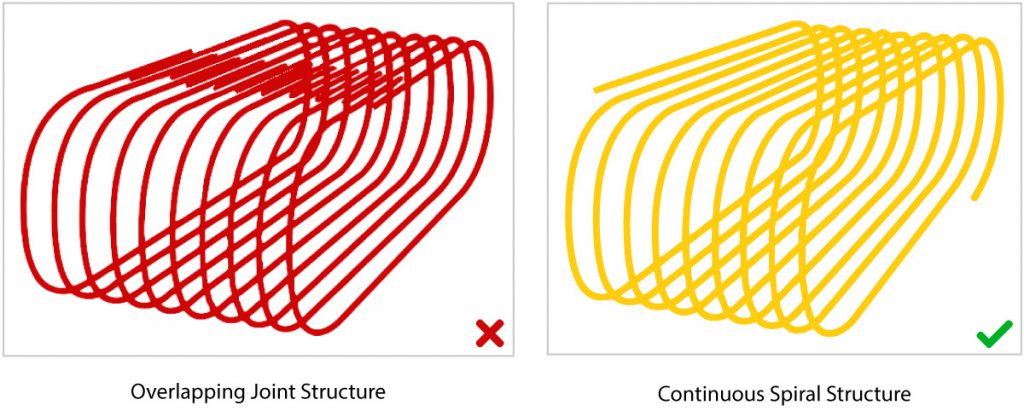

We have been continuously refining our manufacturing process to produce the best aftermarket rubber tracks and will continue to do so to ensure our customers receive a superior product.